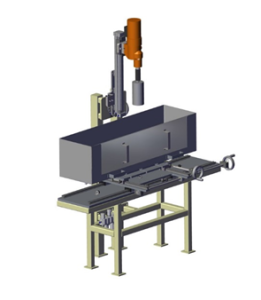

Automated plugging machine

The heavy built diamond tooled drill press is especially designed to drill in various size core samples with an automatic, variable force, constant pressure feed. A constant pressure feed enables the coring bit to drill fast in soft rock, but the rate of advance will automatically slow down in harder rock. The constant pressure feed uses a pneumatic actuator for smooth operation at low rates of advance. The rapid-retract position brings the coring bit out of the rock to a position that will allow removal of the plug from the bit. The coring operation can be performed using water/oil coolant or optionally Liquid nitrogen for unconsolidated samples. The core clamping assembly is mounted on the pan table. An XY table allows for positioning the pan at the right position before drilling the core sample. The head of the drill press can be titled in order to drill the sample in vertical or inclined position.

Automated plugging machine

Features

Coring bit internal diameter: 1″, 1.5″, 2”

Maximum coring depth: 5 inches (12.5 cm), 30 cm (option)

Drip pan dimensions: L x W x H: 1340 x 380 x 340 mm

Coring position: any position from -45° to +45°

Pan position: X: +/- 1000 mm, Y: +/-125 mm

Compatible coolant: Water, Oil , liquid N2 (option)

Drill speed: 550, 1120, 1680 RPM

Electrical: 230 VAC 1 phase, 60 Hz, 11.5 A

Weight: 300 kg

Air: 150 psi

Overall dimensions: L x W x H: 1700 x 680 x 2140 mm